Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

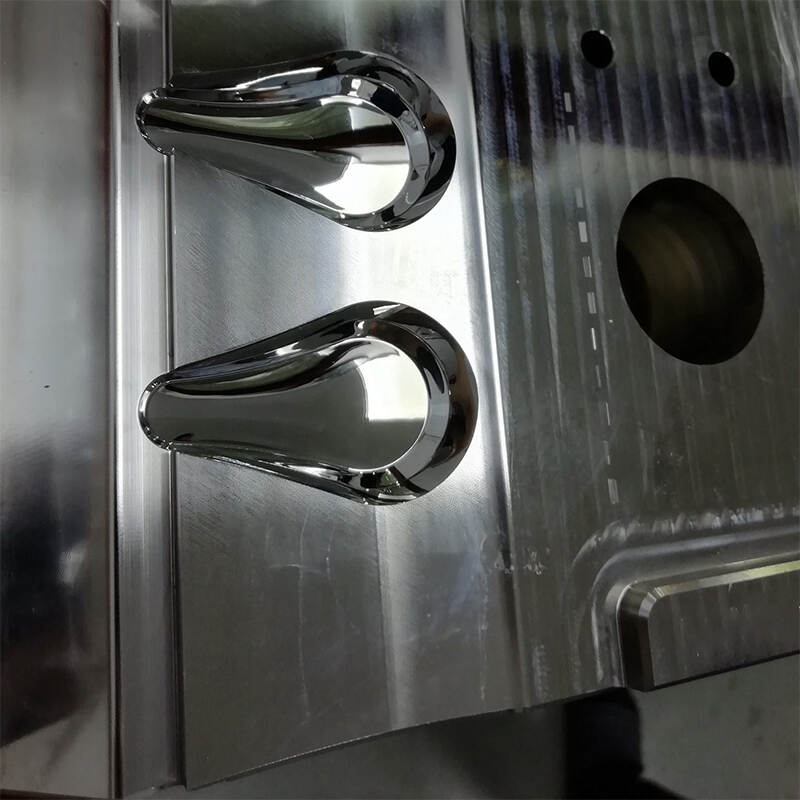

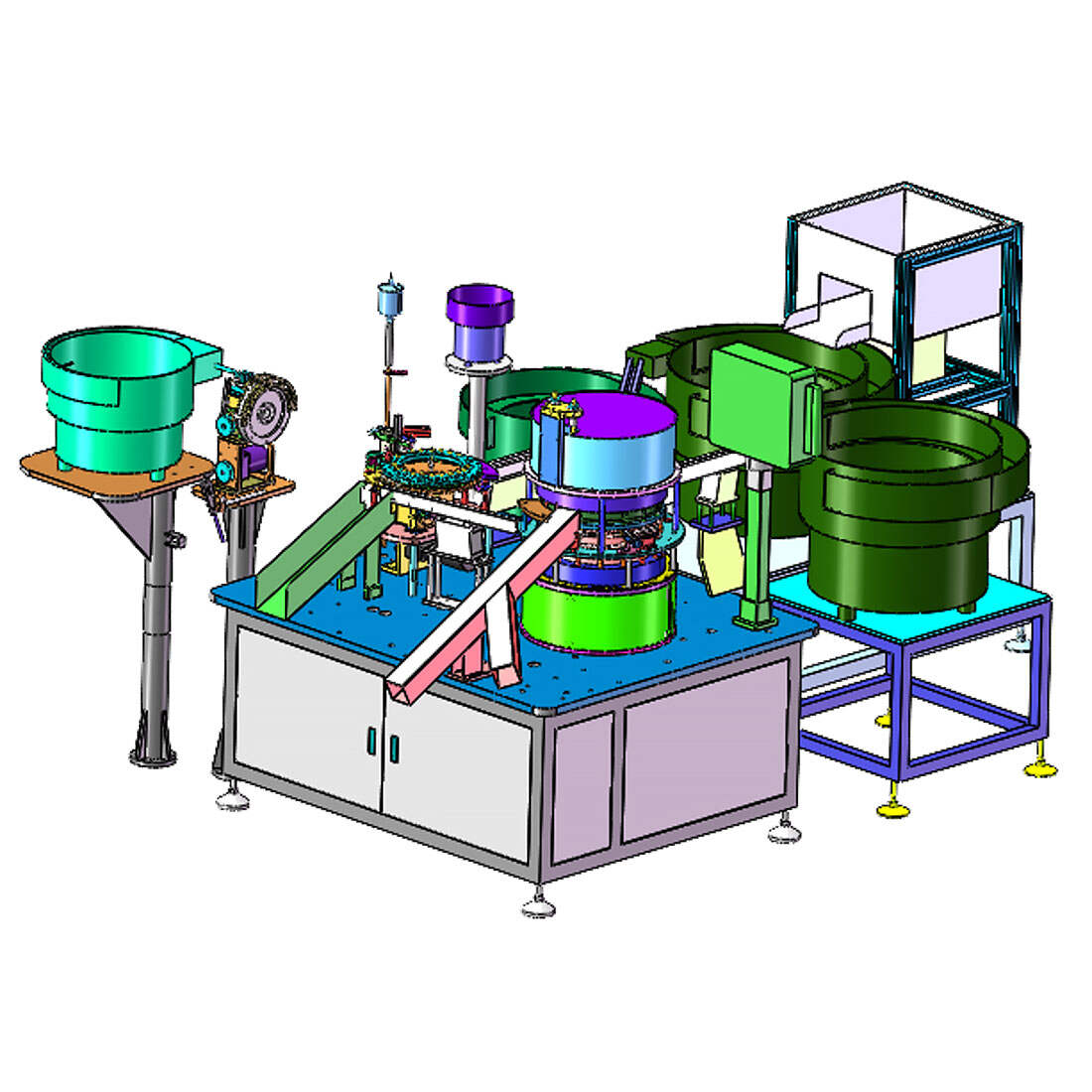

Lotion Pump Injection Mould

The lotion pump injection mold by Songrock epitomizes precision engineering and innovative design. Crafted with meticulous attention to detail and utilizing top-notch materials, this mold ensures the consistent and flawless production of lotion pump components. Whether you're in the cosmetics industry or manufacturing household products, this mold sets the benchmark for quality and reliability.

Description

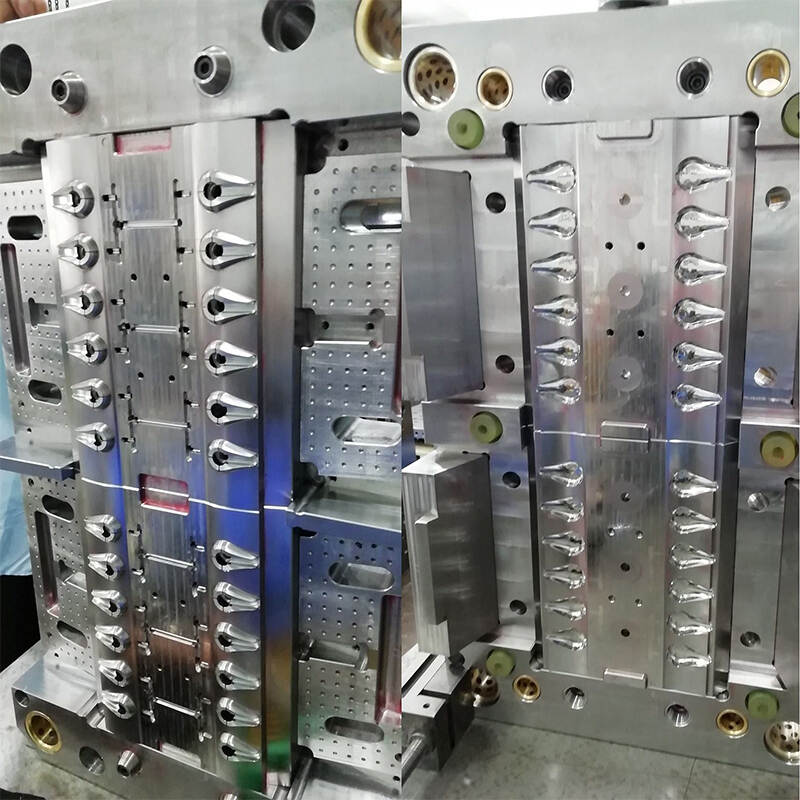

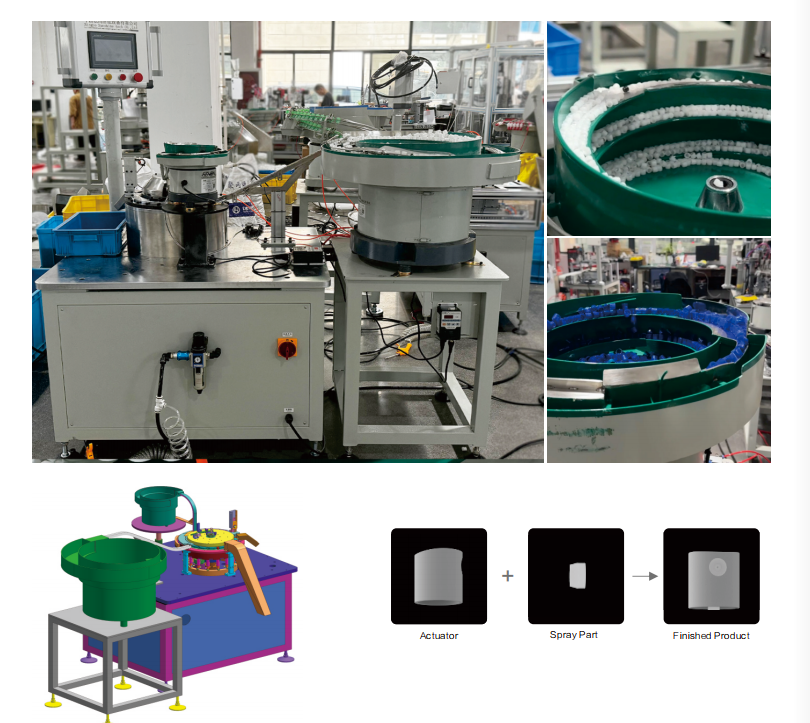

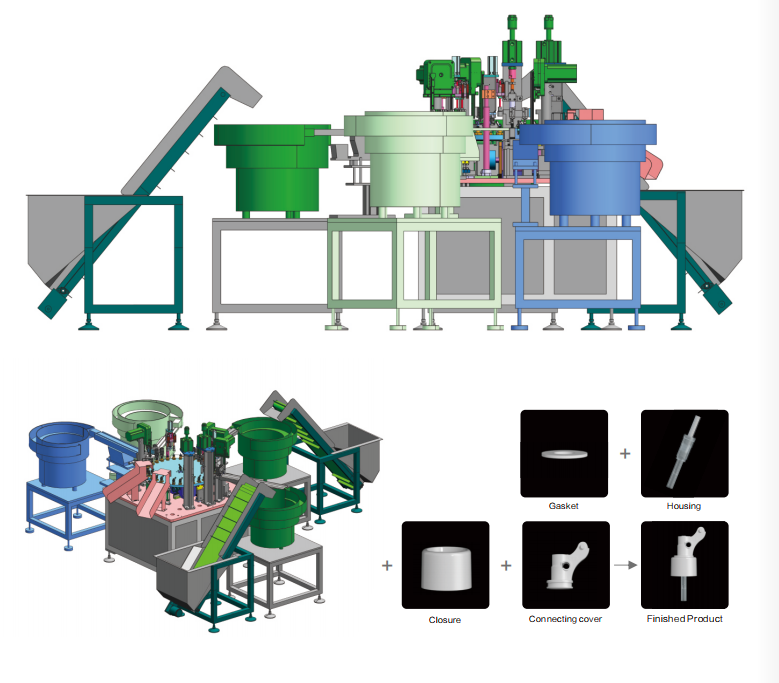

Lotion Pump Injection Mould Designed to meet the exacting standards of modern production facilities, the lotion pump injection mold boasts a robust construction that ensures durability and longevity. Its versatility allows for seamless integration into various manufacturing processes, delivering exceptional results with every cycle. With a focus on efficiency and performance, this mold is engineered to streamline production and optimize output without compromising on quality.

Product Specification

|

Birthplace |

Ningbo, Zhejiang, China |

|

Brand |

Songrock |

|

Product Material |

Steel |

|

Plastic Material |

PP/PE/PET (all plastics) |

|

Product |

Designed and developed according to customers' requirements |

|

Regular-size frame |

45# steel, 50# steel |

|

Mould cavity |

S136, H13, and others according to mold product characteristics |

|

Mould surface |

Polished or sprayed with anti-rust paint according to the customer's requirements |

|

Mold heat treatment |

Cavity sleeve |

|

Mould Life |

Guarantee 100w mold |

|

Design Software |

UG |

|

Packing and shipping |

Packed in a wooden case for export, export molds coated with rust inhibitor, spare parts shipped with molds. |

Lotion Pump Injection Mould Product Features and Advantages

1. Premium Material Composition: Constructed from high-grade steel, the mold offers unparalleled strength and resilience, ensuring consistent performance over countless production cycles. The use of PP, PE, and PET plastics further enhances their versatility, catering to a wide range of product requirements.

2. Tailored Design Options: Customization is at the forefront of this mold's capabilities, allowing for precise adaptation to customers' specifications. From dimensions to surface finishes, every aspect can be tailored to meet the unique demands of the application, ensuring optimum results with each injection.

3. Advanced Heat Treatment: The inclusion of cavity sleeve heat treatment enhances the mold's resistance to wear and tear, prolonging its lifespan and minimizing maintenance requirements. This ensures sustained precision and reliability throughout its operational lifespan, maximizing the ROI for manufacturers.

4. Optimized Design Software: Leveraging cutting-edge design software such as UG, the mold's design is optimized for efficiency and accuracy, facilitating seamless integration into existing production workflows. This ensures swift turnaround times and minimizes lead times, allowing for faster time-to-market for finished products.

5. Comprehensive Packaging and Shipping Each mold is meticulously packed in a wooden case for export, safeguarding it against damage during transit. Additionally, export molds are coated with rust inhibitors, further preserving their integrity. Spare parts are thoughtfully shipped with the mold, ensuring uninterrupted production capabilities.

Lotion Pump Injection Mould Benefits

- Specialized Logistics: Utilization of specialized logistics and freight services ensures efficient handling and transportation of products from the factory to the warehouse, minimizing the risk of delays or damages.

- Sea Freight Options: Sea freight is chosen as the mode of transportation, which is often cost-effective for bulk shipments and offers reliable delivery schedules.

- Professional Guidance: A dedicated team of professionals is available to provide expert guidance and support, offering comprehensive explanations of product use and application methods. This ensures that customers have a clear understanding of how to make the most effective use of the products they purchase.